- • The function expansion option named “MELFA Smart Plus” is available with MELFA FR series.

“MELFA Smart Plus” further broaden the range of possibilities of the MELFA FR series, offering performance beyond your expectations. - • Collaboration with MELSEC Q series/MELSEC iQ-R server series realize more advanced work.

- • Maximum load capacity:3kg to 20kg

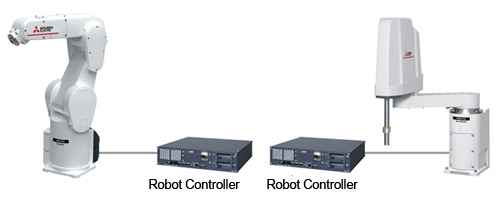

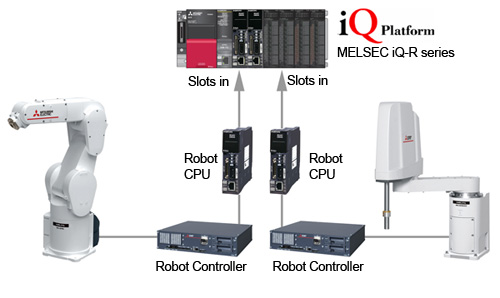

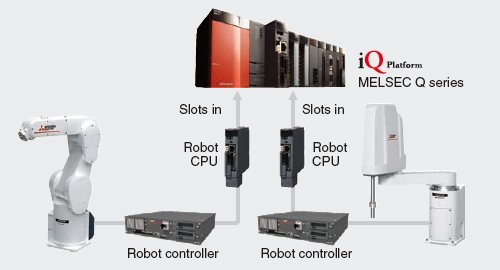

- • Controller TypesR Type: Compatible with the “iQ Platform”. MELSEC iQ-R series-dedicated. (CR800-R controller)

Q Type: Compatible with the “iQ Platform”. MELSEC Q series-dedicated. (CR800-Q controller)

D Type: Standalone controller (CR800-D controller)

Specification

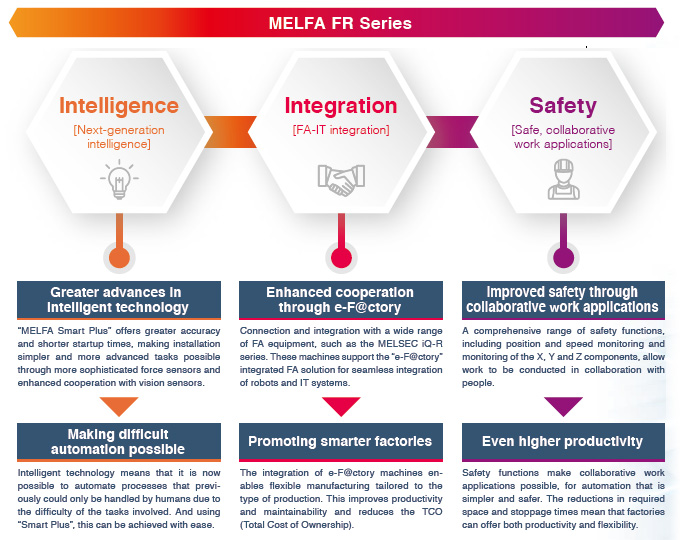

Next-generation intelligence, FA-IT integration, Safe, collaborative work applications

"Next-generation intelligent functions" make it simple to carry out work that has always defied automation.

"Safe, collaborative work applications" allow robots and people to work together with high levels of safety.

"FA-IT integration functions" support nextgeneration manufacturing. With these 3 key features, the FR Series is capable of handling virtually all your automation needs.

Please refer to the "Catalogs" or the "Manuals" for RH-FR series.

MELFA Smart Plus Features

MELFA Smart Plus is an option that brings next-generation intelligence to MELFA FR series robots.

This provides leading-edge functions for all phases of customer's operations, from design and startup through to operation and maintenance. *Activated with the insertion of a Smart Plus card into CR800 controller.

Outline of functions

| Function | Outline of features |

|---|---|

| Predictive maintenance function | Failing drive parts are detected before abnormalities in robot behavior become apparent.Downtime of production equipment is reduced. |

| Preventive maintenance function | Tracking the robot's operating status helps manage the condition of the robot.Maintenance is now even more efficient. |

| Enhancement function for force sense control | Parameters for the optimum operation pattern are found using repeat learning in a short amount of time. Set-up and tact times are reduced. |

| MELFA-3D Vision enhancement function | Reduced startup time thanks to a utomatic parameter adjustments which utilize our proprietary AI technology "Maisart". |

| Calibration assistance function | Easy set-up of 2D v ision sensors and improved job precision. |

| Coordinated control of additional axis | Using a robot with an RTU enables manufacturing and assembly at user specified speeds. (RTU : Robot Transport Units) |

| Robot mechanism thermal compensation function | Compensates for thermal expansion of the robot arm to increase position accuracy. |

Controller features

Improved controller performance

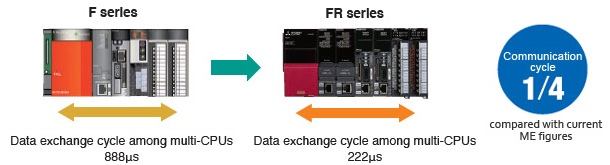

Control cycles on FR series controllers take just half the current time, improving robot control performance. The faster calculation speed gives better robot processing capacity and shorter cycle times for improved productivity. Integration with the various sensors also makes precision operation possible.

R/Q type controller

- This controller is compatible with the "iQ Platform", which seamlessly integrates the various controllers used in a production site with HMIs, the engineering environment and the network.

- It uses a multi-CPU configuration that dramatically improves its interaction with FA equipment and also offers highly precise control and fast yet simple information management.

D type controller

Standalone type- A standalone controller similar to existing models.

- Enables the construction of cells using robot controllers as the control nucleus.

- Comes with various interfaces as standard, allowing customers to build a system optimized for their applications.